Precast Modeling & Shop Drawing Project for Lot 118, Forrestdale, W.A.

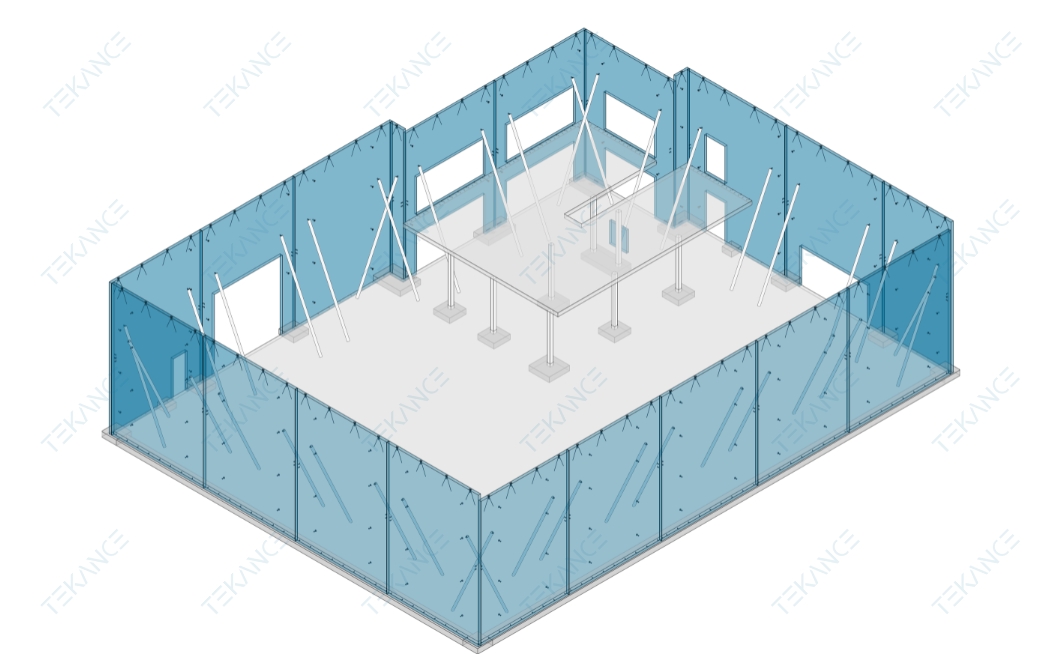

The project at Lot 118, Ayres Road, Forrestdale, Western Australia, involves the development of an industrial facility.

The scope of work includes detailed precast modeling and the preparation of shop drawings for various structural elements, particularly focusing on concrete panels and footings.

The primary objectives of this project were to:

- Ensure Precision in Structural Design: Develop accurate and detailed models that reflect the architectural and engineering drawings, ensuring all structural components are correctly sized, aligned, and positioned.

- Facilitate Efficient Construction: Provide comprehensive shop drawings that guide the fabrication and installation of precast elements, minimizing errors and ensuring compliance with Australian standards.

- Optimize Material Usage: Streamline the design to reduce material waste, ensuring that the structural elements are both cost-effective and robust.

Challenges and Solutions

Complex Structural Requirements

- Challenge: The project required precise alignment of various structural elements, including footings, slabs, and columns, which had to meet specific load-bearing criteria and reinforcement details.

- Solution: Advanced modeling techniques were employed to create detailed 3D representations of the structural components. These models were used to generate shop drawings that provided exact measurements and specifications for each element.

Coordination Between Different Structural Components

- Challenge: The project involved integrating various structural elements such as steel columns, purlins, and concrete panels, which required careful coordination to ensure structural integrity.

- Solution: The project team used BIM (Building Information Modeling) software to integrate the different components into a cohesive model. This approach allowed for the detection of potential clashes and discrepancies early in the design phase, which were then resolved before construction began.

Adherence to Australian Standards

- Challenge: Compliance with the latest Australian standards for structural design, including AS 3600 for concrete structures and AS 4100 for steel structures, was mandatory.

- Solution: The design and documentation were meticulously reviewed to ensure full compliance with all relevant standards. This included detailed checks of reinforcement layouts, concrete cover requirements, and load-bearing capacities as specified in the Australian standards.

Key Features of the Precast Elements

Reinforcement Details

- Panels were reinforced according to the specifications provided in the engineering drawings. For example, typical reinforcement included SL92 mesh placed centrally, with N16 edge bars to ensure structural integrity.

Panel Connections

- Detailed shop drawings provided specifications for all panel-to-panel connections, including the use of panel anchors and connector plates. These details ensured that once erected, the panels would form a continuous and structurally sound wall system.

Custom Features

- The project required some panels to include custom features such as openings for doors and windows, and these were meticulously detailed in the shop drawings to ensure accuracy during fabrication and installation.

Project Outcome

The project was successfully completed, with all panels fabricated according to the detailed designs. The thoroughness of the shop drawings ensured that the installation phase proceeded smoothly, with all panels fitting perfectly as intended. The project met all required Australian standards, resulting in a structurally sound and aesthetically consistent set of precast concrete panels.

Conclusion

This case study underscores the importance of detailed precast modeling and shop drawings in the successful execution of industrial projects. By focusing on precision, compliance, and careful coordination, the project at Lot 118 was able to achieve its structural goals efficiently, setting a high standard for future precast concrete projects.