Precast Panel and Footing Layout Shop Drawings for Industrial

The project involved the preparation and delivery of detailed shop drawings for precast panels and footing layouts for an industrial development located at Lot 112 Ayres Road, Forrestdale, WA.

The scope of work primarily focused on ensuring that the structural elements were accurately depicted for efficient manufacturing, transportation, and installation on-site, adhering strictly to Australian standards and client specifications.

The primary objectives of the project were:

- To provide precise shop drawings for precast concrete panels, including all necessary details for panel dimensions, reinforcement, lifting inserts, and connection points.

- To develop comprehensive footing layout drawings that ensure proper load distribution, stability, and compliance with the geotechnical requirements.

- To coordinate closely with the architectural and engineering teams to integrate structural elements seamlessly into the overall design.

The scope of work included:

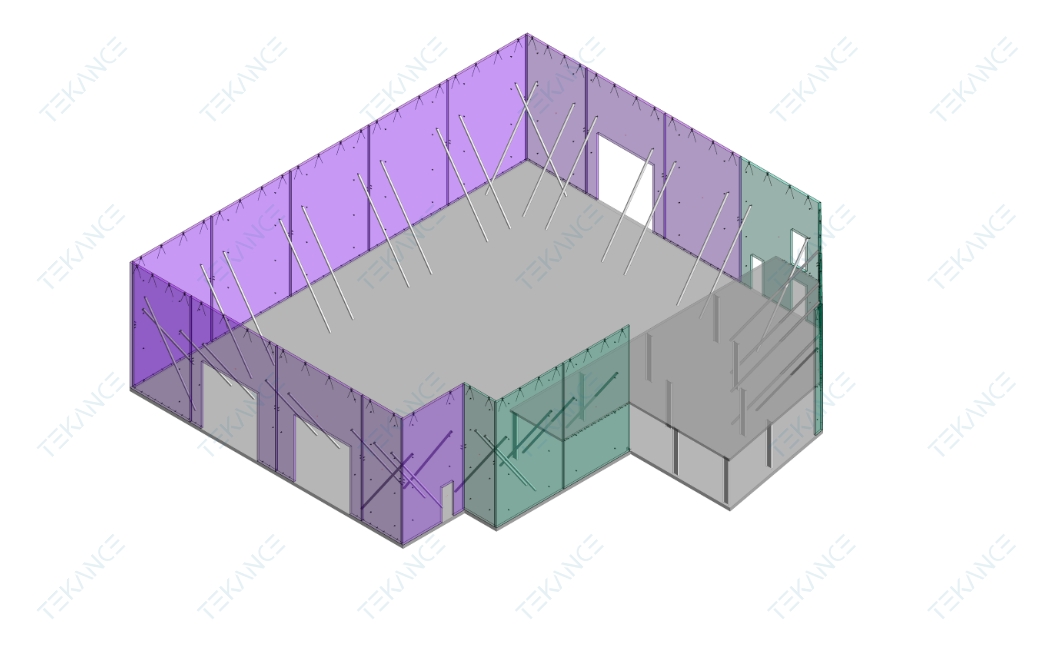

Precast Panel Drawings

Detailed drawings showing the layout and dimensions of each precast panel, including reinforcement details, lifting points, cast-in plates, and connection details to other structural elements.

Footing Layout Drawings

Layouts that depict the exact locations, dimensions, and reinforcement details for all footings, ensuring proper alignment with the structural columns and load-bearing elements of the building.

Integration with Structural Drawings

Ensuring all shop drawings align with the architectural and structural designs, including coordination with other elements like slabs, columns, and beams.

Compliance with Standards

All drawings were prepared in compliance with Australian Standards, specifically AS 3600 for concrete structures, AS 4100 for steel structures, and relevant NCC codes.

Challenges

Coordination Between Disciplines

One of the key challenges was ensuring seamless coordination between the structural, architectural, and construction teams. This required multiple iterations of the drawings to incorporate feedback and adjustments from all parties involved.

Detailing for Constructability

Ensuring the precast panels could be efficiently manufactured, transported, and erected was crucial. This involved precise detailing of lifting inserts, strongbacks, propping points, and connection details to avoid issues during installation.

Site-Specific Adjustments

The geotechnical report highlighted specific site conditions that required adjustments in the footing designs, particularly in terms of compaction requirements and differential footing levels.

Outcomes

Successful Delivery

The shop drawings were delivered before time and met all specified requirements. The precision in detailing facilitated smooth fabrication and erection processes on-site.

Client Satisfaction

The client was satisfied with the level of detail and accuracy in the drawings, which minimized on-site adjustments and potential delays.

Compliance and Safety

The project adhered to all relevant standards, ensuring the structural integrity and safety of the development.

Conclusion

This project highlights the critical role of accurate and detailed shop drawings in the successful execution of construction projects. By focusing on precision, coordination, and compliance with standards, the project team was able to deliver a high-quality product that met the client’s expectations and contributed to the overall success of the industrial development at Lot 112 Ayres Road.