How Can We Help

+91 - 3225 796 221

support@tekance.com

Download Brochure

Precast Detailing Services in {City}

Tekance provides top-notch precast detailing services in {city}, delivering accurate shop tickets and fabrication drawings for panels, columns, beams, walls, frames, and other precast elements.

If you’re looking for a dependable partner to handle any precast detailing project in {city}, we’re here to help.

Over the past 8 years, we’ve worked with clients worldwide, focusing on the ever-growing construction industry.

We’ve completed many projects, including detailing, shop drawings, and modeling. The positive feedback from our clients says it all about the quality of our work!

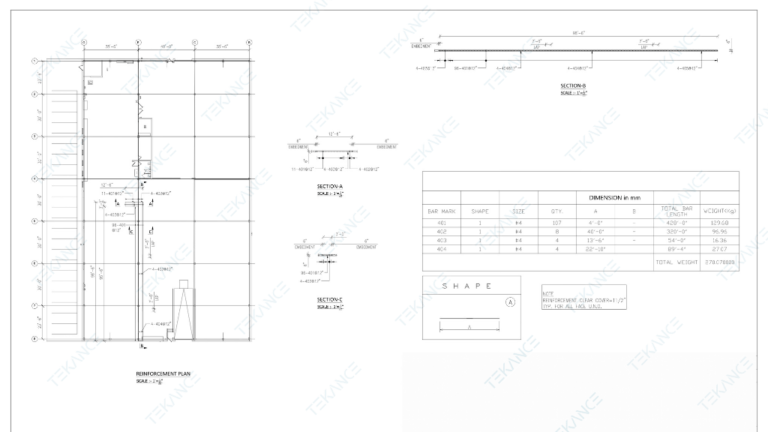

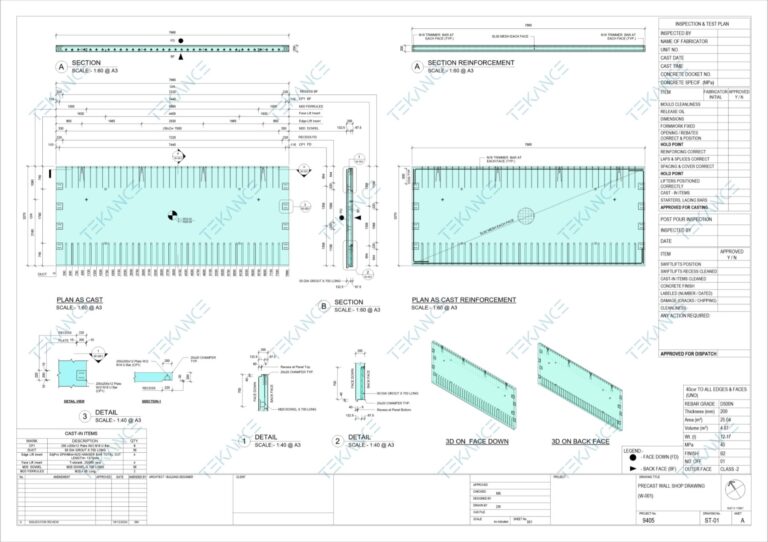

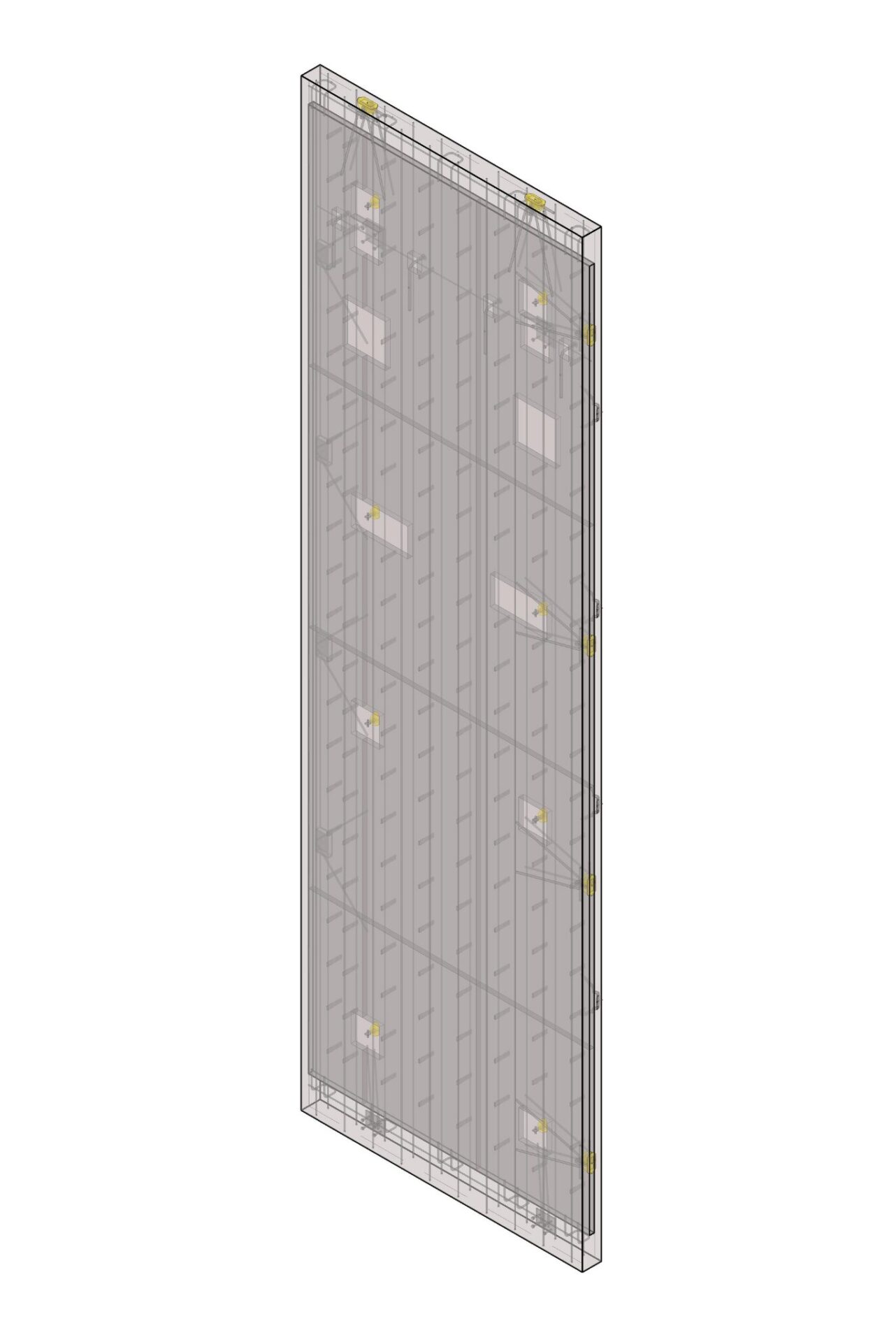

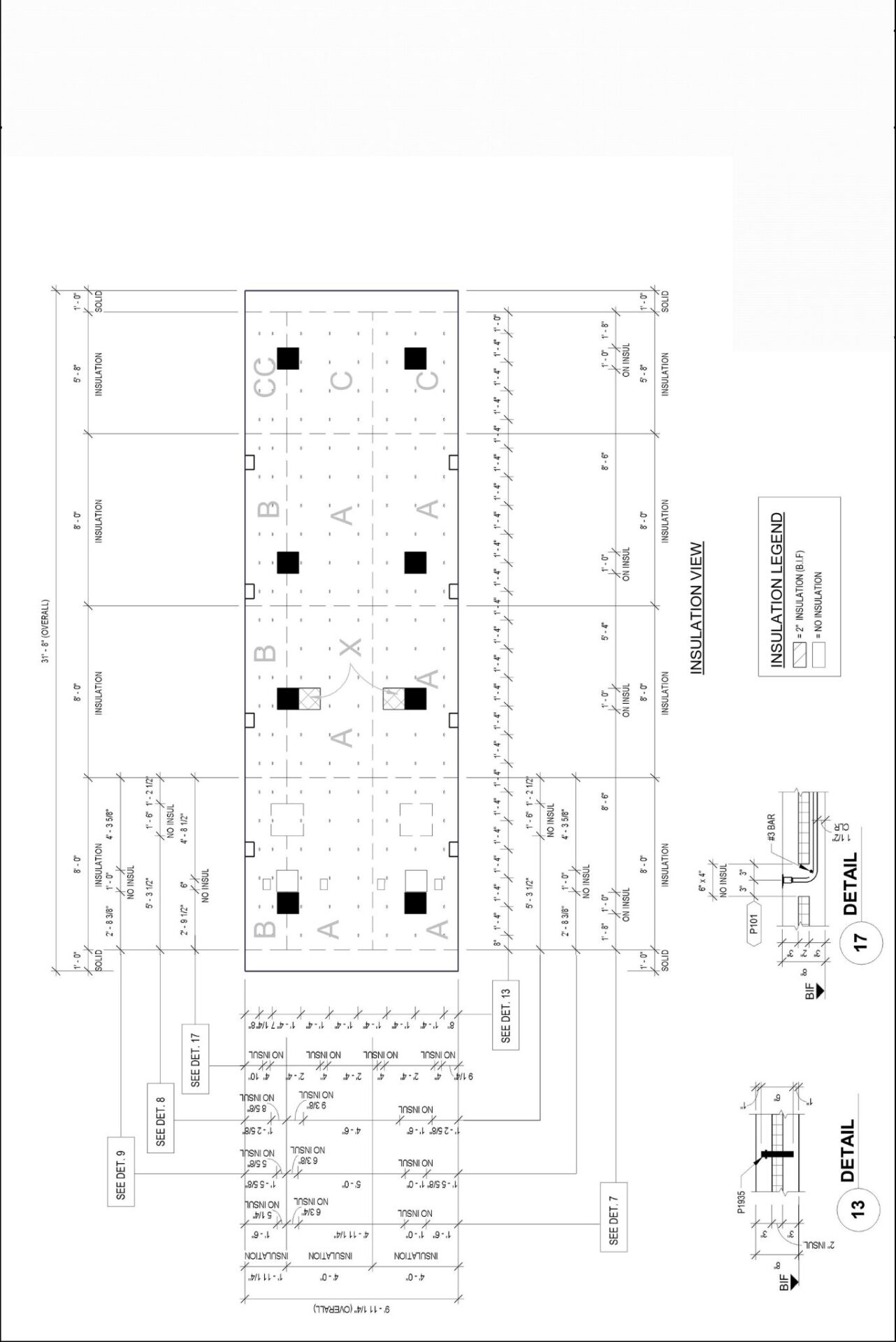

Precast Shop Drawings

Detailed blueprints for manufacturing precast elements.

02.

Erection Drawings

Instructions for assembling precast components on-site.

Bar Bending Schedules

Specifications for reinforcing steel placement.

Marking Plans

Layout for identifying and positioning precast elements.

05.

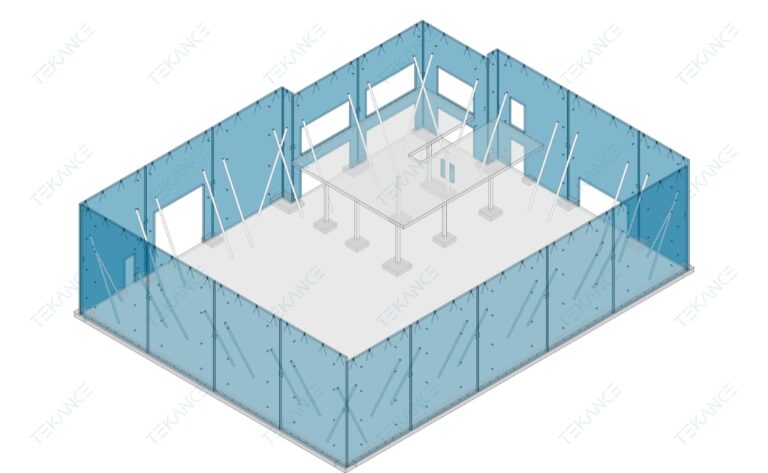

Wall Panel Detailing

Includes various types like sandwich, solid, double, and tilt-up panels.

06.

Beam and Column Detailing

Covers different shapes, sizes, and reinforcement layouts.

07.

Slab Detailing

Includes flat slabs, hollow core slabs, and double tee slabs.

08.

Stair Detailing

Covers precast stair components and their connections.

09.

Embedment Detailing

Specifies embedded items like anchors, sleeves, and conduits.

10.

Lifting Leg Locations

Determines points for safely lifting precast elements.

11.

Grout and Ferrule Locations

Details locations for grouting and connecting elements.

12.

Quantity Take-offs

Generates material quantities for estimating and procurement.

13.

BIM Coordination

Integrates precast models with other building components.

14.

Cladding Panel Detailing

Focuses on exterior precast panels.

15.

Shear Wall Panel Detailing

Details high-strength wall panels for structural support.

16.

Double Wall Detailing

Specializes in walls with two concrete layers.

17.

Curtain Wall Panel Detailing

Details exterior cladding panels.

18.

Precast Beam-Column Connection Detailing

Focuses on critical junctions.

Featured projects

Standards We Follow for Precast Panel Detailing in {city}

We stick to most of the industry standards used in Australia. At the same time, we make sure to adapt to the specific construction standards preferred by our clients, all while maintaining the rules for advanced design, detailing, and construction.

- AS 3600 – Concrete Structures

- AS 3850 – Precast Concrete Elements

- AS/NZS 1170 – Structural Design Actions

- AS 2159 – Piling Design and Installation

- AS/NZS 4671 – Steel Reinforcing Materials

- AS 5100 – Bridge Design

- AS/NZS ISO 9001 – Quality Management Systems

- AS 1720 – Timber Structures

- AS 2870 – Residential Slabs and Footings

- AS 4100 – Steel Structures

Why Choose Our Precast Detailing Services in {city}

Our team of precast modelers in {city} has over 8 years of experience and is skilled in using advanced software like AutoCAD, RebarCAD, CADS RC, Tekla Structures, and Revit, to name a few.

At Tekance, we offer services for a wide range of structures, including commercial and institutional buildings, multi-level buildings, industrial structures, chemical plants, residential buildings, foundation structures, bridges, and modular structures.

With experience spanning over 100 structural projects, we focus on delivering top-notch customer satisfaction. Our detailing work is done with the highest standards of quality, consistency, and a smooth workflow.

Accuracy & Precision

We guarantee high-quality CAD and BIM models that eliminate errors and streamline your construction process.

Cost-Effective Solutions

Our services are designed to offer the best value for your investment, making us a trusted partner for businesses of all sizes.

Expert Team

Our professionals bring years of experience in precast detailing and are committed to delivering exceptional results.

Quick Turnaround Times

We work efficiently to meet tight deadlines without compromising on quality.

Our Software Expertise

Our Precast Detailing Workflow

Project Inception

We initiate the process by closely collaborating with clients to understand project requirements, architectural designs, and structural specifications.

Structural Analysis

Our engineering team conducts thorough structural analysis to determine load-bearing capacities, material requirements, and reinforcement details.

3D Modeling

Detailed 3D models of precast components are created using advanced software to visualize and optimize designs.

Shop Drawing Creation

Precision shop drawings are generated, outlining dimensions, reinforcement layouts, and fabrication details for each precast element.

Quality Assurance

Rigorous quality checks are performed to ensure accuracy, compliance with standards, and constructability.

Delivery and Support

Finalized shop drawings are delivered, and our team provides ongoing support during the precast production and construction phases.